Custom retractable Heely wheels hidden in the heel of a Nike Air Force 1.

Custom retractable Heely wheels hidden in the heel of a Nike Air Force 1.

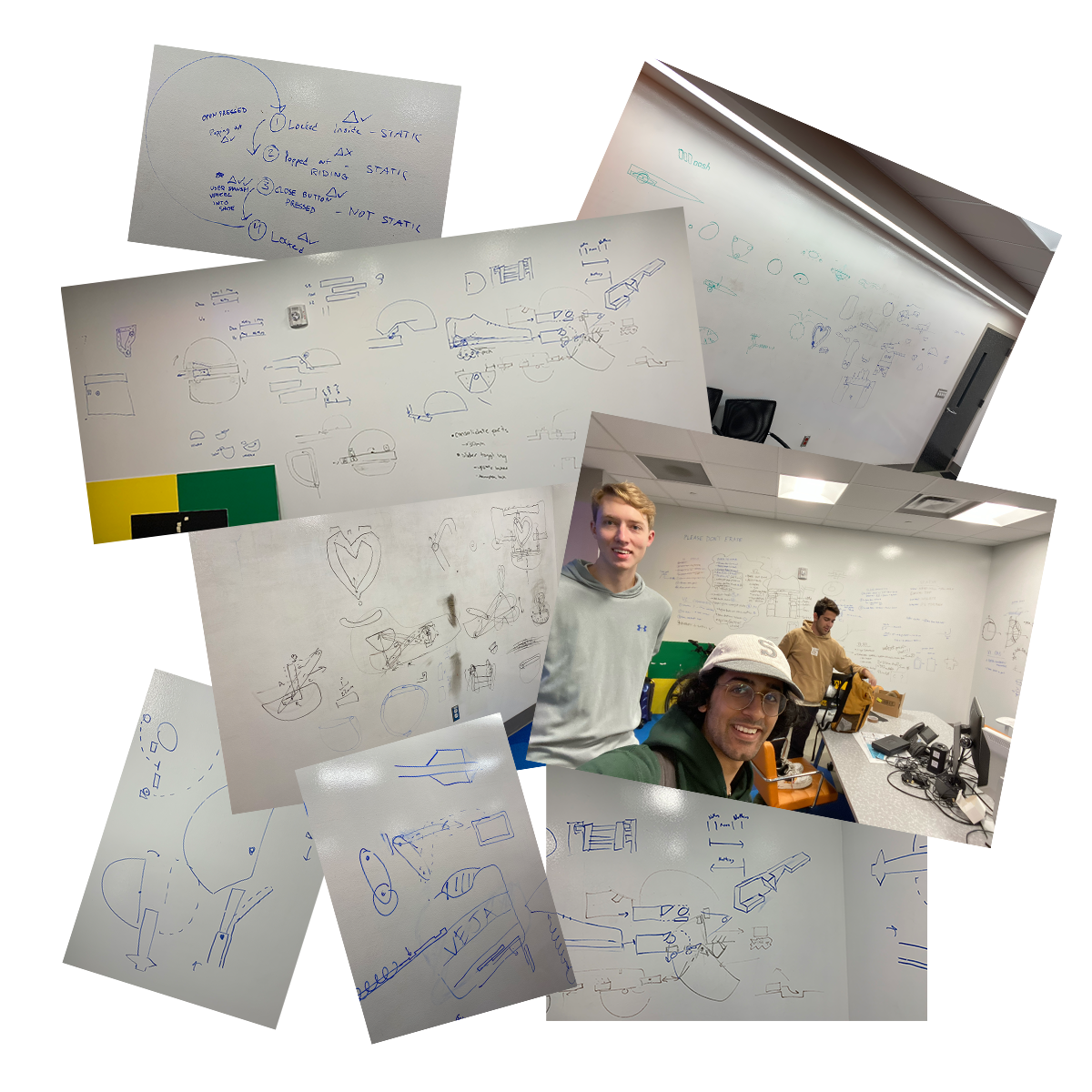

We began filling whiteboards with concept designs and structures. It was immediately obvious that the problem was a deceptively difficult one; small mecahnisms typically don't like the weight of a human standing on them. Needing to "reinvent the wheel," we explored everything from using multiple semicircular wheels to a folding wheel. Eventually we found a solution: multiple 10mm roller bearings arranged around a 40mm circle could effectively "simulate" the feeling of a much bigger wheel at a much smaller volume.

After a whirlwind design and fab sprint, we finally had a finished product...

A button hidden beneath the rubber of the heel shifts a springloaded slider, allowing the wheel assembly to switch between the walking (up) and skating (down) states.

To improve robustness and reliability we reduced the number of parts to the greatest extent possible. Discounting shafts, bearings, and bolts, the final design is composed of only 5 main parts. However, the parts we did have to make were extremely machining intensive; of all the geometry on the parts, there is only one stock face!

The team. From left: Mohsin Haider, myself, and Fran Romano.